In 2015 a representative office of the Lekhim Group of Pharmaceutical Companies was opened in the Republic of Uzbekistan, which actively developed a mutually beneficial partnership between Ukraine and Uzbekistan in the field of registration and supply of medicines.

On July 04, 2019, Foreign Enterprise Limited Liability Company “LEKHIM” (abbreviated name - FP "LEKHIM" LLC) was incorporated according to the laws of the Republic of Uzbekistan.

At present FP "LEKHIM" LLC is actively constructing modern pharmaceutical facilities for manufacture of finished dosage forms in the Republic of Uzbekistan.

The conceptual project of a pharmaceutical complex for manufacture of finished dosage forms at the Republic of Uzbekistan, Tashkent Region, Karamurt Street, Mahalla Birlik, Durmon Village, Kibray District

STAGE 1 – manufacture of injectable drugs in ampoules (aseptic manufacturing) with a capacity of 150 million pieces per year;

Administrative building; power unit; laboratories of the quality control department (QCD);

warehouse complex for input materials, materials, finished dosage forms for the capacity of this production complex.

The period of commissioning in view of the release of finished dosage forms makes 7 years.

STAGE 2 - manufacture of injectable drugs in vials (dry powder) with a capacity of 15 million pieces per year;

STAGE 3 - manufacture of hard dosage forms in the form of tablets, capsules, sachets with a capacity of:

tablets - 500 million pcs. per year;

capsules - 150 million pcs. per year;

sachets - 50 million pcs. per year;

The new designed pharmaceutical complex shall comply with the requirements of EU GMP international norms and rules, and the current norms and rules of the Republic of Uzbekistan.

The designed sites will be provided with electricity, drinking water, heating water, process steam and compressed air from the networks of the enterprise.

To maximally protect products from contamination and cross-contamination, some of production facilities have been designed as clean premises. The designed production facilities involve manufacture of non-sterile and sterile finished products; therefore, some of the premises are designed for B, C and D cleanliness classes in accordance with EU GMP.

Technical solutions at subsequent stages of designing can be specified and changed according to the results of consideration and approval of these conceptual solutions and revised/amended Technical Assignment for Designing.

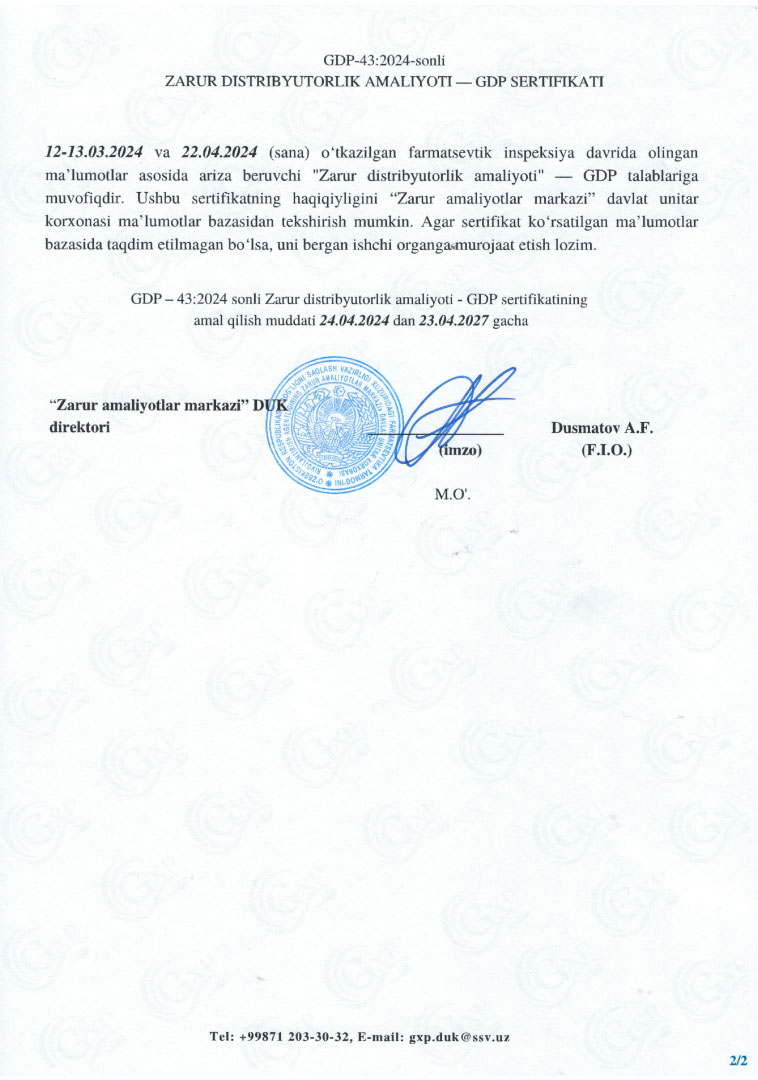

Our certificates: